This is a continuation of the last post about Steel Windows.

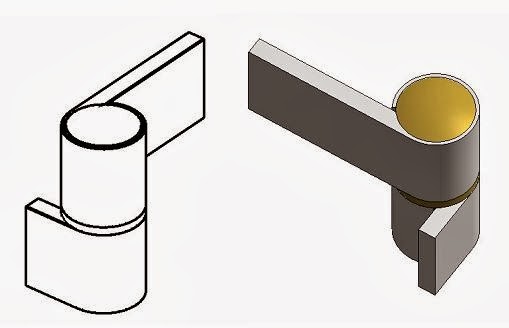

So I got the handle done & it rendered up nicely. Next in line was the peg stay for a top-hung light. (sash, light, casement ... what's with all these seemingly interchangeable words ... truth is that's just the way language works: lot's of redundancy & overlap, constantly shifting ground, rules that bend)

I was still feeling may way into these components, modelling by trial and error, but by the time I got to the screws I decided to make a separate family that could be copied around.

It was actually rather fun trying to model from memory and then finding references on the internet to guide me through the confusion. You can use something a thousand times and think you know it well, but drawing it out in detail is another matter. Try drawing a map of the world from memory for example. Any teacher knows this very well. You don't just stand there and talk to your students. You have to get them doing something that challenges their abilities and understanding.

So I've captured the basics of these brass fixtures. The dimensions are still very approximate, and to be honest I'm still not 100% sure how some of the moving parts work. i.e. how are they held securely in place while permitting angular movement ? This has to be done with the minimum of fuss, allow for manufacturing tolerances, plus wear and tear. Low tech by current standards but 100 years ago these were important contributions to daily life.

There are fixing lugs on the sides of the windows that are built in to the wall by the bricklayer. I'll do another post sometime on how this works, something that was once a part of my daily routine. For now I am content to make a family that cuts a hole in the wall and place my window into this. I'm keeping the two families separate for the moment to reduce my confusion while working in family editor. The opening family uses voids (not cut openings) This allows me to step the opening in plan and section.

The sill detail I chose is fairly common in Zimbabwe. It uses special, small size clay bricks with a bullnose edge, sill bricks in fact. I modelled whatever is visible from the outside, to a reasonable degree of accuracy, and filled in the hidden detail with drafting. Classic BIM methodology.

A short aside. Many of you will be familiar with the ribbon glitch that has been with us for some time now. While making a sweep and clicking on "edit profile", the buttons you want disappear. You'll see a greenish tab at the back, click this to restore normality. I'm assuming this is a rogue behaviour that is difficult to track down in all the lines of code. That's better than believing that the factory can't be bothered to fix it. While working on this study, I noticed that this problem only occurs when working in plan view. If you're working in section/elevation everything works fine. Curiouser and curiouser.

More benefits of the BIM pencil: throwing views on to sheets. This always draws a gasp of amazement when teaching newbies, and rightly so. I've said it before, but Revit is my favourite DTP software ... but it could be even more favouriter, if only they would add some extra DTP features with each new release (hint to the factory) By the way, see how I am adding subtleties of expression by bending/breaking the rules of language. We all do this, all the time ... but if you're a secret language pedant, you just block it out and pretend that language is strictly logical. Duhh !!!

And so to the end of my post. (no verb in that sentence, nor in this one actually) I rounded it off by assembling a window with side-hung, top-hung and fixed panes. It's a standard type from the catalogues but it's not fully parametric & the opening is still separate from the glazed frame. Still it serves my current purpose amirably: fit for purpose, the golden rule.

I have a couple of images of the hinge family that I made, so I'll throw those in to finish off. Timber sashes and standard steel windows, that covers the types of building I lived in for most of my life. So I guess aluminium sliders are next, that's what I've had for the last 10 years, here in the middle east.

thank for the wonderful post , lots of information gained , visit us Revit Modeling in uk

ReplyDelete