Steel takes an edge. For centuries it was the material of tools and weapons: carpentry, warfare & agriculture.

I grew up in South Yorkshire while it was still a land of coal and steel. For most of my twenties I lived in Sheffield, birthplace of crucible steel, and later the of the Bessemer process. By 1850 steel had become the material of bridges, machines, railways. Cast iron predated steel for structural use in buildings, notably in "fire-proof" factory construction. Cast iron columns carried beams similar to railway lines in section, with brick jack-arches spanning between the beam

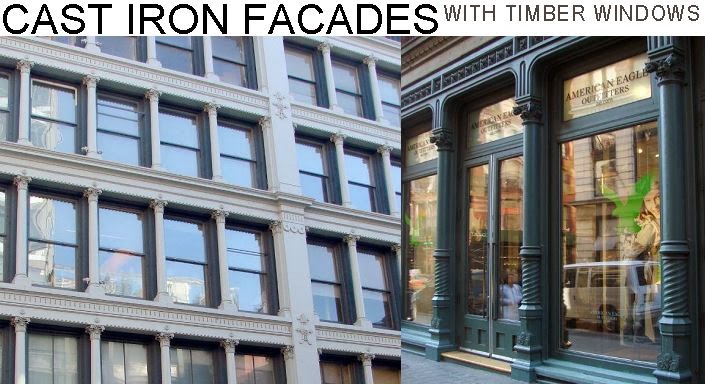

5 or 6 years ago I photographed some of the famous cast-iron facades in Soho, New York. These were an early example of prefabrication: modular facades created in the factory and assembled on site. It's interesting to note that behind the decorative/structural cast iron there are often timber sliding-sash windows.

One of the best known examples is the Singer building. It seems to me though that much of this is not cast iron, but steel: heated and bent, riveted together. Even the window frames seem to be steel. We are approaching an era when steel seemed to be the ideal material for window frames, and glazing of all types.

Charles Rennie Mackintosh got in there early, using steel windows in 2 school buildings in Glasgow (Scotland Road & the School of Art) Is he a modernist or a traditionalist ? abstract geometrist or arts & crafts flower person ? Nobody seems to be quite sure.

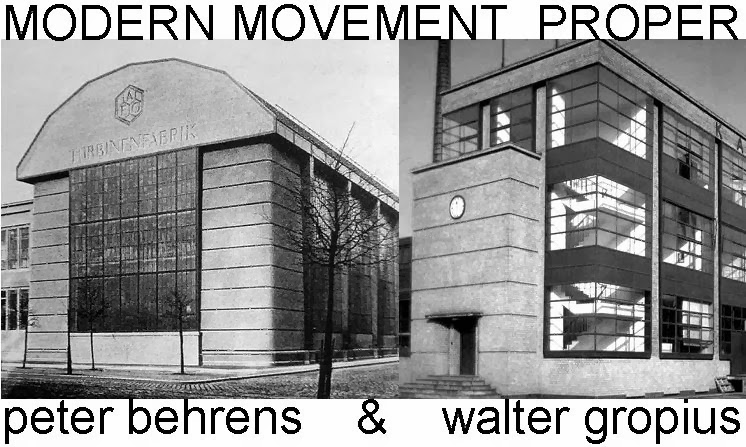

Just over a decade later Peter Behrens and his former employee Walter Gropius designed buildings that have become famous for their steel-framed glazing. Technically I think this is very similar to Mackintosh, but they did without his subtle decorative flourishes and projected the glazing in front of the masonry. So everyone is quite cetain that they are modernists.

Mass-produced steel windows in standard sizes, ("off-the-shelf") became very popular in the 20s and 30s, rapidly replacing the wooden sliding sash. But the heyday of steel windows in Europe lasted barely 50 years. Disruptive innovation or blip on the screen? By the 1970s it was clear that condensation related corrosion was a serious problem, and U values were becoming important.

So when I moved to Southern Africa in 1981, I thought of steel windows as an anachronism, an outmoded technology. But in a dryer and warmer climate, where neither central heating nor air conditioning are needed in the average house, steel windows dominated the market.

I spend my first decade in Africa as a teacher & curriculum developer, returning to architecture as I approached 40. As an architect, I used steel frames most of the time. They are the ideal solution for the Zimbabwean climate and economy. (We used to have an economy in the first 80s & 90s)

I am using BIM techniques to explore how buildings work, how they have varied in time and place, the processes and trades involved in making them. I am NOT making families for everyday use in projects. That is a separate exercise.

Typically, an experts advice on making families will start with an injunction to plan ahead, to sit down with pencil and paper to plan out the parameters and reference planes you will need. That is not what I am about here. Revit IS my pencil, my planning tool. I am using it to work something out. In the case of the brass handles and stays, or the steel hinges, there are elements that belong to the sash and elements that belong to the outer frame; elements that move in space and elements that stay where they are. There are pivot points and angular movements. Ultimately it would be nice to articulate all that, to make it parametric and represent top-hung or side-hung lights with the sashes in different positions by punching numbers into dialogue boxes.

But first I need to understand how these things work. I have to get the sizes and shapes right. That is an exploratory process. I don't have any steel windows to hand. I can't just fly back to Zimbabwe and measure the ones in my house there. I have to work from grainy photographs and internet downloads, plus my memories of fiddling with windows that didn't close properly or had loose handles.

Let's take the handle for a side-hung sash. A door handle sits in a horizontal position when at rest, but you don't want the window handle to spoil your view, so it hangs down when the window is closed.

In making this handle, I wanted it to look fairly convincing, without getting sidetracked by Revit technicalities. The goal was to understand the main points of the design: how it works and why it is shaped like that. So I haven't rounded off all the sharp edges and I haven't gone to the trouble of using conceptual massing to capture the complex curves. I made do with an extrusion cut by a couple of voids. Building components should be "fit for purpose", not under-designed or over-designed. The same goes for drawings: be they pencil sketches or BIM models. (I could have said "BIMs" but I think that would have been both clumsier and less clear) So my aim here is to do just enough to capture the essence of how these fittings work.

But let's look at the window itself. If you look in text books, you can find all kinds of refined details, with weather stripping and aluminium glazing beads. Steel windows been reborn in a higher-tech form. But this post is staying low-tech, the basic window that I know from my time in Zimbabwe. Standard "Z" section, putty glazed. The same "Z" section serves for outer frame and for hinged sash.

Notice the little heel on the back of the "Z". This forms a groove to channel water around the sides. In case of driving rain, you might get some water that needs to be directed in this way to the bottom and out again. The same groove it the outer frame helps to key the frame into the internal render. Internal plastering in Zimbabwe uses a sand-cement mix, not the lightweight gypsum base coat that I was used to in the UK. Again it has to do with climate and the economics of material production.

I'm going to break off there and post this. I've been far too quiet this last 2 months, got to get something out there. Part 2 will follow shortly.

I grew up in South Yorkshire while it was still a land of coal and steel. For most of my twenties I lived in Sheffield, birthplace of crucible steel, and later the of the Bessemer process. By 1850 steel had become the material of bridges, machines, railways. Cast iron predated steel for structural use in buildings, notably in "fire-proof" factory construction. Cast iron columns carried beams similar to railway lines in section, with brick jack-arches spanning between the beam

5 or 6 years ago I photographed some of the famous cast-iron facades in Soho, New York. These were an early example of prefabrication: modular facades created in the factory and assembled on site. It's interesting to note that behind the decorative/structural cast iron there are often timber sliding-sash windows.

One of the best known examples is the Singer building. It seems to me though that much of this is not cast iron, but steel: heated and bent, riveted together. Even the window frames seem to be steel. We are approaching an era when steel seemed to be the ideal material for window frames, and glazing of all types.

Charles Rennie Mackintosh got in there early, using steel windows in 2 school buildings in Glasgow (Scotland Road & the School of Art) Is he a modernist or a traditionalist ? abstract geometrist or arts & crafts flower person ? Nobody seems to be quite sure.

Just over a decade later Peter Behrens and his former employee Walter Gropius designed buildings that have become famous for their steel-framed glazing. Technically I think this is very similar to Mackintosh, but they did without his subtle decorative flourishes and projected the glazing in front of the masonry. So everyone is quite cetain that they are modernists.

Mass-produced steel windows in standard sizes, ("off-the-shelf") became very popular in the 20s and 30s, rapidly replacing the wooden sliding sash. But the heyday of steel windows in Europe lasted barely 50 years. Disruptive innovation or blip on the screen? By the 1970s it was clear that condensation related corrosion was a serious problem, and U values were becoming important.

So when I moved to Southern Africa in 1981, I thought of steel windows as an anachronism, an outmoded technology. But in a dryer and warmer climate, where neither central heating nor air conditioning are needed in the average house, steel windows dominated the market.

I spend my first decade in Africa as a teacher & curriculum developer, returning to architecture as I approached 40. As an architect, I used steel frames most of the time. They are the ideal solution for the Zimbabwean climate and economy. (We used to have an economy in the first 80s & 90s)

So this is the next installment in my "window technology" series, standard steel windows: the Crittall Hope variety. I should explain once more what I am doing. For BIM to really succeed it must become second nature to all participants in the Construction Industry. We should use it as naturally as picking up a pencil, or sketching a detail in chalk, on the wall inside a building site. So my focus is not to track the latest devices and software tools. Others do that much better than I could. I am trying to use Revit like a pencil: a tool with which to explore ideas, clarify my thoughts, make sense of what I have learnt over the years; in short, an aid to visual thinking.

I am using BIM techniques to explore how buildings work, how they have varied in time and place, the processes and trades involved in making them. I am NOT making families for everyday use in projects. That is a separate exercise.

Typically, an experts advice on making families will start with an injunction to plan ahead, to sit down with pencil and paper to plan out the parameters and reference planes you will need. That is not what I am about here. Revit IS my pencil, my planning tool. I am using it to work something out. In the case of the brass handles and stays, or the steel hinges, there are elements that belong to the sash and elements that belong to the outer frame; elements that move in space and elements that stay where they are. There are pivot points and angular movements. Ultimately it would be nice to articulate all that, to make it parametric and represent top-hung or side-hung lights with the sashes in different positions by punching numbers into dialogue boxes.

But first I need to understand how these things work. I have to get the sizes and shapes right. That is an exploratory process. I don't have any steel windows to hand. I can't just fly back to Zimbabwe and measure the ones in my house there. I have to work from grainy photographs and internet downloads, plus my memories of fiddling with windows that didn't close properly or had loose handles.

Let's take the handle for a side-hung sash. A door handle sits in a horizontal position when at rest, but you don't want the window handle to spoil your view, so it hangs down when the window is closed.

In making this handle, I wanted it to look fairly convincing, without getting sidetracked by Revit technicalities. The goal was to understand the main points of the design: how it works and why it is shaped like that. So I haven't rounded off all the sharp edges and I haven't gone to the trouble of using conceptual massing to capture the complex curves. I made do with an extrusion cut by a couple of voids. Building components should be "fit for purpose", not under-designed or over-designed. The same goes for drawings: be they pencil sketches or BIM models. (I could have said "BIMs" but I think that would have been both clumsier and less clear) So my aim here is to do just enough to capture the essence of how these fittings work.

But let's look at the window itself. If you look in text books, you can find all kinds of refined details, with weather stripping and aluminium glazing beads. Steel windows been reborn in a higher-tech form. But this post is staying low-tech, the basic window that I know from my time in Zimbabwe. Standard "Z" section, putty glazed. The same "Z" section serves for outer frame and for hinged sash.

Notice the little heel on the back of the "Z". This forms a groove to channel water around the sides. In case of driving rain, you might get some water that needs to be directed in this way to the bottom and out again. The same groove it the outer frame helps to key the frame into the internal render. Internal plastering in Zimbabwe uses a sand-cement mix, not the lightweight gypsum base coat that I was used to in the UK. Again it has to do with climate and the economics of material production.

I'm going to break off there and post this. I've been far too quiet this last 2 months, got to get something out there. Part 2 will follow shortly.

Nice topic Andy. Steel section windows are still popular in most of the Asian countries like in India. I think profiles for steel section windows should be available on Autodesk Seek. Go ahead.

ReplyDeleteAndy,

ReplyDeleteThanks for sharing this post, I grew up with the same kind of steel windows in Hong Kong when I was a kid. Your handles reminds me of how they work, and they leak when there was a typhoon. Many of these windows gradually got replaced with aluminium frame window in the 90s.

Thanks guys. Interesting to know where else steel windows have been popular. I can imagine that they would struggle with a typhoon though.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi

ReplyDeleteHi, I was simply checking out this blog and I really admire the premise of the article this is regarding and this is really informative. I will for sure refer my friends the same. Thanks dave burke

I enjoyed going through this blog as you have thrown light (excuse the pun) on the use of glass doors and windows. I would personally recommend Vision AGI for anything related to glass installation. Their team is highly skilled and guarantees a ‘proper’ installation really quickly without causing any damage.

ReplyDeleteawesome

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteLaminated glass in Palakkad

ReplyDeleteSteel Building Construction Gujarat - Akurai is one of the few PEB companies that offers its clients a complete building system. Reliable construction of pre engineered steel buildings.

ReplyDeletehttps://akuraipeb.com/steel-building-construction-gujarat-india.html

Such a beautiful content, Please keep posting article like this

ReplyDeleteERP software in chennai

Nice Post! Thanks for sharing such an informative blog. I will definitely share this informative blog with others. In recent years steel structures is widely used to construct various commercial and industrial buildings like steel warehouse building and more.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteI've been following the advancements in Pre-engineered building technology, and it's amazing to see how they continue to evolve, becoming stronger and more efficient. Pre-engineered building

ReplyDeleteThe precision and accuracy in PEB construction are outstanding. These buildings are a testament to the importance of engineering excellence. PEB construction

ReplyDeleteIzhar Steel takes pre-engineered building construction to new heights. Their innovative approach and state-of-the-art techniques make them a go-to choice for quality projects.

ReplyDeletePre-engineered building

Pre-engineered building (PEB)

The way your blog talking about construction of window is insightful. We also believe in procurement of quality material for construction of warehouse construction you can find more information about our Procurement vertical.

ReplyDeleteThanks for sharing the valuable Post

ReplyDeleteI recently had the pleasure of working with STEEL & GLASS on a construction project, and I must say, their expertise and professionalism exceeded my expectations. From the initial consultation to the final installation, their team demonstrated a high level of skill and attention to detail.

The installation process was seamless and efficient. The team worked diligently to ensure that every element was properly installed, paying close attention to even the smallest details. The result was a flawless finish that exceeded my expectations.

I highly recommend STEEL & GLASS for steel warehouse building or any construction or architectural project that requires steel and glass elements.

Security Glass in Kerala

ReplyDeleteThanks for sharing your blog on the steel using for tools. If you are looking for a reliable steel distributor then you must visit BK steel company in Ludhiana.

ReplyDeleteThis comment has been removed by the author.

ReplyDelete"Building with glassreliable commercial glass companyreliable commercial glass company is an architectural dance of transparency and innovation. The sleek façade of glass structures not only mirrors modernity but also invites a symphony of light, creating a dynamic and captivating environment where the boundaries between indoors and outdoors gracefully blu

ReplyDeleteNice blog about rigidity of steel and its relation between glass. Taking all the responsibilities and trust from long time makes BK steel the best Steel distributor in Ludhiana. Looking foward to serve you.

ReplyDeleteExcel In Your Exams With Our Expert Test Preparation Services! At Sistem Tutoring, We Offer Tailored Solutions Through Both In-Person Tutoring And Virtual Tutoring Sessions. Our Experienced Tutors Provide Personalized Guidance, Ensuring You Grasp Key Concepts And Ace Your Tests. Choose The Flexibility Of Virtual Tutoring Or The Traditional Approach Of In-Person Sessions For Effective And Comprehensive Test Preparation. Elevate Your Academic Success With Our Dedicated Tutoring Support

ReplyDeleteThinking about renovating your London, Ontario home? There's nowhere else to look! Our living room has seen an amazing makeover since we just refurbished it.

ReplyDeleteHome renovations in London, ON

The relationship between shades of gray and building glass lies in the aesthetic professional commercial glass company and functional aspects of architectural design. When architects incorporate various shades of gray into a building's exterior or interior, they often consider using different types of glass to achieve specific effects.

ReplyDelete"The sleek design of glass commercial doors not only enhances aesthetics but also invites transparency, creating a welcoming and modern business ambiance."

ReplyDeleteMalabou - Your Trusted Steel Fabrication Supplier in NZ!

ReplyDeleteWelcome to Malabou, the leading Steel Fabrication suppliers in NZ ! As a trusted name in the industry, we offer top-quality steel products for all your construction and manufacturing needs. Our team of skilled professionals ensures precision and excellence in every project, delivering custom solutions that exceed expectations.

With years of experience, we pride ourselves on delivering outstanding customer service and tailored solutions to meet your unique requirements. From structural steel and metal fabrication to welding services and more, we've got you covered. Trust Malabou for superior quality, value, and reliability in steel fabrication in NZ. Contact us today!

DGU glass manufacturers in Kerala

ReplyDeletecommercial concrete is symbiotic, forming the backbone of modern architectural design and construction. Steel and glass often complement each other in contemporary buildings, with steel providing structural masonry support and glass offering transparency and aesthetic appeal. Meanwhile, commercial concrete serves as the foundation and framework upon which both steel and glass are integrated, ensuring stability and durability in commercial structures

ReplyDeleteThank you so much for sharing this blog with Unique us. It provides a collection of useful information. Metal building construction is rapidly changing the landscape of modern architecture.

ReplyDeleteGet The Perfect Storage Solution For Your Massage Gun With Our Premium Gun Holder For Wall. Purchase Today And Elevate Your Wellness Routine By Keeping Your Device Secure, Accessible, And Ready For Use. Ideal For Any Home Or Gym Space, Our Gun Holder Ensures Your Investment Is Protected And Beautifully Displayed. Don'T Miss Out—Purchase Your Gun Holder For Wall Now And Transform Your Recovery Experience.

ReplyDeleteAluminum extrusions are known for their exceptional properties that distinguish them. Their lightweight quality ensures easy handling and installation, highlighting their versatility across various industries. Additionally, their impressive durability makes them a reliable choice for sectors such as construction and automotive. These extrusions excel in their corrosion-resistant features, ensuring long-lasting performance in a diverse range of applications. Explore the wide selection of aluminum extrusions available today to find the perfect solution tailored to your specific needs and preferences!

ReplyDelete

ReplyDeleteNice Blog. Such a beautiful content, Please keep posting article like this structural steel building construction

TMT bars will without a doubt stay at the front of underlying greatness, directing the way toward a more secure, stronger future.

ReplyDeleteSTEEL & GLASS" and pressure wash services lies in the maintenance and cleanliness aspect. Pressure washing is an effective method for Pressure Wash Services South Carolina cleaning both steel and glass surfaces, ensuring they remain pristine and free from dirt, grime, and other contaminants.

ReplyDeleteDiscover The Perfect Solution For Storing Your Theragun With Our Sleek, Durable Theragun Mount. Effortlessly Integrate Your Massage Gun Into Your Home Or Gym Space, Ensuring It'S Always Within Reach When You Need It Most

ReplyDeleteGreat Post! You are sharing a wonderful post. Thanks and keep sharing. Steel frame industrial buildings offer robust structural support for various industrial applications. Their strength, durability, and versatility make them ideal for warehouses, factories, and manufacturing plants. Steel frames provide ample space for machinery, equipment, and storage while allowing for flexible layouts and future expansions. Additionally, they are resistant to fire, pests, and adverse weather conditions, ensuring the safety and longevity of the industrial facility. For a comprehensive overview of steel frame industrial buildings, including latest trends, expert opinions, and actionable tips, please visit this page and stay ahead of the curve.

ReplyDeleteHi guys

ReplyDeleteIt can also be heat treated to improve its strength, hardness, and durabilityBest Carbon Steel Hammer in India so you can visit site our blog

Purchase The Ultimate Wall Mount Solution For Massage Guns, Expertly Designed To Keep Your Device Secure And Accessible. Our Wall Mount Is Engineered For Durability And Ease, Ensuring Your Massage Gun Is Always Ready When You Need It. Get The Perfect Blend Of Functionality And Style With Our Sleek, Space-Saving Design. Ideal For Home Gyms, Clinics, Or Personal Spaces, This Wall Mount Solution For Massage Guns Is A Must-Have For Any Wellness Enthusiast. Elevate Your Relaxation Routine With Us Today!

ReplyDeleteHigh Quality Toughened glass in Kerala

ReplyDeleteInnovative Tools for Modern Public Safety Challenges

ReplyDeleteEnsure public safety with cutting-edge tools designed for modern challenges. Explore innovative solutions that enhance security and efficiency in urban environments.

Nice articles and your information valuable and good articles thank for the sharing information Pre Engineering Steel Building (PEB)

ReplyDeleteIT Support companies in UK

ReplyDeletebuy IT Equiment in uk

I recently came across some amazing properties on Ambergris Caye Real Estate. The stunning use of steel and glass in many of these homes perfectly blends modern elegance with the natural beauty of the island. It's truly a paradise for those who appreciate sophisticated architectural design!

ReplyDeleteThankyou for sharing such as Informative blog. Your blog is really amazing keep sharing this kind of useful information with us and check out our website.

ReplyDeletemobile welding brisbane

The Building and Construction Experts in London, ONat Apeiro Construction in London, ON are excellent! Their dedication to excellence and attention to detail have completely changed our house. I heartily endorse using their services!

ReplyDeleteThanks for sharing this valuable information about metal, steel and aluminium fabricators. If you want to explore more term related to metal fabrications, then must visit https://chanceymetals.com/. We offer metal, steel and aluminium fabrications services at reasonable price. To get in touch with us: 904.260.6880

ReplyDeleteSecuring a nursing job in Australia from India involves several key steps. Firstly, ensure you have completed a nursing degree that is recognized by the Australian Nursing and Midwifery Accreditation Council (ANMAC). Secondly, pass an English language proficiency test such as IELTS or OET, as required by the Nursing and Midwifery Board of Australia (NMBA). Next, apply for a skills assessment through ANMAC to verify your qualifications and experience. Following a successful skills assessment, register with the Australian Health Practitioner Regulation Agency (AHPRA). After obtaining AHPRA registration, you can start applying for nursing positions in Australia. Additionally, you will need to apply for an appropriate visa to live and work in Australia. It is also beneficial to familiarize yourself with the job market and potential employers. Finally, networking with other healthcare professionals and joining relevant online forums can provide valuable insights and opportunities.

ReplyDeletehttps://dynamichealthstaff.com/nursing-jobs-in-australia-for-indian-nurses

Thank you very much for sharing the valuable blog with us. Keep sharing helpful information.

ReplyDeleteconstruction company in Ontario

Dr. Rajesh Malhotra is a renowned onco-surgeon based in Gurgaon, specializing in advanced surgical interventions for breast cancer. With over two decades of experience, he has mastered techniques such as sentinel lymph node biopsy and breast reconstruction, offering patients optimal outcomes and faster recovery. Known for his meticulous surgical skills and compassionate bedside manner, Dr. Malhotra is dedicated to providing personalized care. He collaborates closely with a multidisciplinary team to ensure comprehensive treatment plans tailored to each patient's unique needs. Dr. Malhotra's commitment to ongoing research and innovation keeps him at the forefront of cancer treatment advancements, making him a highly trusted and respected figure in the Gurgaon medical community.

ReplyDeletehttps://www.breastoncosurgery.com/know-the-doctor/profile

Dr. Rajesh Desai is heralded as one of the leading neuroendocrine cancer surgeons in Ahmedabad, renowned for his surgical precision and compassionate patient care. With over fifteen years of expertise in managing complex neuroendocrine tumors, he leverages minimally invasive techniques to ensure swift recoveries. Dr. Desai is deeply committed to crafting personalized treatment plans that address both the unique medical and emotional needs of his patients. His practice features state-of-the-art technology, providing the highest standards of care. Highly regarded within the medical community for his meticulous skills and empathetic approach, Dr. Desai prioritizes continuous patient education, offering clear guidance and unwavering support throughout the treatment process.

ReplyDeletehttps://drvirajlavingia.com/services/neuroendocrine-cancer-specialist-in-ahmedabad

Dr. Kavita Menon is a renowned breast cancer specialist in Mumbai, celebrated for her exceptional diagnostic acumen and innovative treatment strategies. With a wealth of experience in managing intricate breast cancer cases, Dr. Menon designs personalized treatment plans tailored to each patient's unique needs. Leveraging the latest technology and minimally invasive techniques, she ensures high precision and treatment effectiveness. Actively involved in clinical research, Dr. Menon contributes significantly to the advancement of breast cancer therapies. Her empathetic approach and clear communication provide patients with confidence and support throughout their treatment journey. Dr. Menon's dedication to excellence and patient-centric care establishes her as a leading authority in breast cancer treatment in Mumbai.

ReplyDeletehttps://drnitanair.com/contact/contact-dr-nita-nair-mumbai

Thanks for sharing this amazing informative post with us i found this helpful for top-quality custom steel fabrication in brisbane. Contact us for custom steel fabrication in Brisbane and Brendale.

ReplyDeletecustom steel fabrication brisbane

Sustainable glass manufacturers in Kerala

ReplyDeleteDr. Shona Nag is a leading breast cancer surgeon in Pune, celebrated for her unparalleled expertise in oncological care. She specializes in advanced surgical techniques and creates personalized treatment plans tailored to each patient's needs. Dr. Nag is adept at minimally invasive procedures, ensuring quicker recovery and excellent patient outcomes. Her dedication to research and participation in clinical trials place her at the forefront of medical advancements. She emphasizes a compassionate care model that addresses both the physical and emotional well-being of her patients, fostering a holistic healing environment. Dr. Nag’s relentless commitment to excellence makes her a trusted name in breast cancer surgery.

ReplyDeletehttps://www.drshonanagbreastcancer.in/understanding-cancer/what-is-cancer-can-cancer-be-cured

Steel and glass create a stunning, modern aesthetic, blending strength with elegance. Their synergy in architecture results in sleek, luminous spaces, epitomizing contemporary design. Ideal for creating open, airy environments, steel and glass structures not only look impressive but also offer durability and sustainability. Swastik Factory Private Limited is a leading dealer of laminated glass in Odisha. Their top-quality products ensure safety and durability, perfect for both residential and commercial uses. Their commitment to excellence and customer satisfaction sets them apart.

ReplyDeleteLow cost website design in Delhi serves as a practical option for businesses aiming to create an effective online platform within budgetary limits. These services emphasise user-friendly interfaces and attractive visuals, ensuring that even budget-conscious brands can stand out in a crowded digital market. Designers are skilled in employing contemporary design practices and tools, which facilitate the development of responsive websites adaptable to any device. A collaborative process is often adopted, allowing clients to provide feedback and request multiple revisions for a final product that meets their expectations. Additionally, many designers integrate vital features such as SEO optimisation and basic e-commerce capabilities, further enhancing the website's functionality. By focusing on quality and efficiency, low-cost website design options empower small businesses to establish a robust online presence, ultimately supporting their growth and success without excessive financial strain. Such investments not only help in attracting potential customers but also contribute to developing a solid brand identity in the digital landscape.

ReplyDeletehttps://olycoder.com/low-cost-website-design

Nice Post visit for commercial glass manufacturer

ReplyDeleteMinoxidil is a widely recognized over-the-counter treatment for hair loss in Australia, specifically targeting male pattern baldness. Applied as a topical solution, it needs consistent use—twice daily for optimal results. Its efficacy lies in its ability to dilate blood vessels, thereby enhancing blood circulation to the hair follicles. Users typically observe noticeable hair regrowth within several months, though individual outcomes may vary. The most common formulation for men is the 5% concentration. While generally safe, users should be aware of potential side effects like scalp irritation. It is always advisable to follow the product instructions carefully. Consulting with a healthcare professional can further minimize risks and maximize benefits.

ReplyDeletehttps://generichealth.com.au/minoxidil-hair-loss/

When seeking a reliable divorce lawyer near you, consider the expertise and client-focused approach of a trusted advocate like Rajkumar Solanki in Delhi. A well-regarded professional, he adeptly manages intricate family law cases, providing guidance in child custody, alimony, and asset distribution. His negotiation skills help foster amicable resolutions, reducing conflict and stress. Solanki's empathetic method ensures strategies are customized to fit individual circumstances. Transparency and open communication define his practice, fostering a strong sense of trust. With dedication to safeguarding clients' interests, he prioritizes their long-term stability and well-being. Known for both his compassionate guidance and formidable legal prowess, Solanki is a top choice for those navigating the complexities of divorce.

ReplyDeletehttps://bestdivorcelawyerindelhi.com/

Thanks for share this information with us this will help a lots of people if you are serching for commercial door hardware visit their.

ReplyDeleteThank You.

ReplyDeleteNice blog, thanks for sharing about steel and glass. Steel and glass combine strength and elegance, creating stunning structures that stand the test of time. Swastik Factory Private Limited offers a stunning range of decorative mirrors that enhance any space with elegance and style. Their craftsmanship and attention to detail are truly impressive, making them a go-to supplier for high-quality glass products. Whether for home or commercial use, their mirrors add a touch of sophistication that elevates interior design. Highly recommend!

ReplyDeleteYour insights into the durability and elegance of steel-glass structures are spot on. It’s amazing how these materials blend to create timeless designs.

ReplyDeleteVisit for commercial window glazing

ReplyDeleteApeiro Construction is the best option if you want a construction business that genuinely hears your demands and realizes your vision. In London, Ontario, their proficiency and dedication to excellence are unparalleled.

ReplyDeleteconstruction companies london ontario

New Life Steel stands at the forefront of PEB steel manufacturing, offering innovative and reliable pre-engineered building systems peb steel manufacturer We specialize in creating strong, durable structures for a variety of industries, including manufacturing, warehousing, and commercial sectors. Our advanced technology and experienced engineers design buildings that are both functional and cost-effective

ReplyDeleteWhether you need warehouses, industrial units, or agricultural facilities peb steel structure New Life Steel provides versatile PEB steel structures. Engineered for longevity and performance, our pre-engineered buildings meet the highest standards while offering cost savings and fast assembly.

ReplyDeleteUse EKCO Cleaning Services to uphold hygienic standards! Brisbane gym cleaning services for a healthier training environment.

ReplyDeleteGym cleaning service Brisbane

Thanks for sharing the valuable Post ! This was a fantastic read :) Your website is not only informative but also well-structured and engaging. Also Check, BIM services for construction projects

ReplyDeleteExcellent article highlighting the elegance of steel and glass combinations! It's inspiring to see such innovative uses of materials. Swastik Factory Private Limited is proud to be the top laminated glass dealer in Odisha, delivering high-quality and reliable glass solutions.

ReplyDeleteInformative post. Thanks for sharing.

ReplyDeleteTop peb supplier

This Kickstarter campaign supports an exciting independent sci-fi action feature film that champions creativity and small businesses. By backing this project, you’re not only fueling the vision of passionate filmmakers but also empowering local artists and entrepreneurs involved in production. This thrilling film promises a unique, high-energy Back this project narrative crafted outside the studio system, and your support helps bring it to life. Join the movement—support indie cinema , uplift small creators, and be part of something original. Comment: Downloading this film once released is more than just entertainment—it's a statement of support for indie filmmakers and small business collaboration

ReplyDeleteGreat article

ReplyDeleteExcellent post. Thanks for sharing.

ReplyDeleteCrane Building Manufacturer in Delhi

The Classic English Door is more than just an entryway — it’s a statement of elegance, proportion, and heritage. At Quartier Studio, we honor the beauty of tradition while seamlessly blending it with modern sensibilities. Every panel, every hinge, every curve tells a story of refined taste and enduring style

ReplyDeleteInteresting

ReplyDeleteAmazing work!!

ReplyDeleteI really like your hard work and you can also read our interesting blog here EN8 CARBON STEEL

ReplyDeleteFind Genuine ACE CRANE SPARE PARTS for all models at Partsmith.ae – your trusted supplier in the UAE. We stock original spare parts for ACE Hydra Cranes, ACE NXP Cranes, ACE FX Series Cranes, ACE NextGen Cranes, ACE Pick & Carry Cranes, and more. Whether you're maintaining ACE 12XW, 14XW, 15XW, 20XW, or 25XW cranes, we provide high-quality replacement parts to ensure your crane’s performance and reliability. Fast delivery, competitive prices, and genuine quality – only at Partsmith.ae.

ReplyDeleteNice blog!!

ReplyDeleteAmazing blog!!

ReplyDeleteI like your content and you can also read blog here EN8 CARBON STEEL

ReplyDeleteA great read highlighting the aesthetic and structural synergy of steel and glass! For those exploring durable glazing options, Swastik Factory Private Limited stands out as a leading DGU Supplier with reliable and high-quality products. Truly a name you can trust in architectural glass solutions!

ReplyDeleteWhether you’re brand new to meditation or have a regular practice, the guided sessions at Bronxville Wellness provide tools and techniques that can be Relaxing Massage Mount Vernon used both on and off the cushion. Meditation is more than relaxation—it is a practice of awakening, allowing you to move through life with greater awareness, intention, and calm.

ReplyDeleteNice blog!!

ReplyDeleteI like your content and appreciate it and you can also read our interesting blog about EN8D GRADE STEEL

ReplyDeleteReliable Construction Servicesdeliver quality workmanship, on-time project completion, and durable results you can trust for residential, commercial, or industrial needs

ReplyDeleteProfessional new construction window services provide precise installation of high-quality, energy-efficient windows that enhance both style and performance. Ideal for residential and commercial projects, these services ensure durability, proper fitting, and long-term value while improving comfort and curb appeal.

ReplyDeleteOur clinic offers comprehensive care with a strong focus on ADHD (Attention Deficit Hyperactive Disorder), providing personalized treatment plans that address the unique challenges of this condition. With an ADHD specialty, our experts guide patients in managing focus, impulsivity, and daily routines effectively. In addition, we provide professional support for Depression and Anxiety, ensuring holistic mental health solutions. Our goal is to empower individuals with tools and therapies that enhance overall well-being, resilience, and long-term emotional balance.

ReplyDeleteCitizen Metals offer an inclusive range of stainless steel fasteners such as SS 316 Bolts, SS 316L Nuts, SS 316H Screws, SS 316Ti Washers, and SS 316 Stud.

ReplyDeleteNeelcon Steel Industries are supplier of Stainless Steel 310 Pipe used in high temperature. Wide stock of 310 Stainless Steel Erw Pipe in round, square & rectangular shapes.

ReplyDeleteFor specialized Titanium Grade 2 Plate Manufacturer in India and Engineered Tested Plates for Industrial Environments, contact Kanakratna Steelage.

ReplyDeleteAll Duplex 2205 Seamless Pipe produced according to the ASTM A789 must be furnished in a heat treated condition. This heat treatment performed on the Duplex 2205 Pipe must be keeping with accordance to the specified temperature and quench conditions.

ReplyDeleteGanpat Industrial Corporation are Stainless Steel Pipe Manufacturers who carries a full inventory of SS Pipes and Tubes products in a variety of sizes to meet the structural piping requirements for applications of water, petroleum, oil & gas and other industries.

ReplyDeletePurchase ASTM A53 Grade B Pipe from suppliers who are certified by the government or any agency like L.G. Pipes and Tubes.

ReplyDeleteBy combining professional guidance with supportive Wellness Teacher Bronxville community environments, wellness training helps individuals cultivate sustainable healthy habits and achieve their personal wellness goals.

ReplyDeleteSpiritual growth and holistic wellness have become essential for many individuals seeking balance in today’s fast-paced world. A Spiritual Teacher NYC offers guidance, support, and practical tools for navigating life’s challenges while fostering inner peace and personal development.

ReplyDeleteGreat insights! Become a Home Appliances Authorized Distributor

ReplyDeleteis truly a smart business opportunity in today’s growing market. The article clearly explains the benefits and steps involved, making it easier for new entrepreneurs to understand how to partner with reliable brands and start their journey in the home appliance industry. Thanks for sharing such valuable information!

ACE cranes are powerful machines, and using genuine spare parts makes a big difference. I always order from partsmith.ae, totally reliable source.

ReplyDeleteDon’t compromise on performance — choose original ACE Crane Spare Parts from Partsmith.ae. Our products are built to meet manufacturer standards, ensuring maximum efficiency and safety. Visit partsmith.ae and order authentic ACE parts that keep your cranes working strong.

Need an accurate and efficient way to calculate flange weights for your projects? Dinesh Industries brings you the flange weight calculator, a simple yet powerful tool designed to help you quickly determine the weight of flanges based on their size and material. Save time, reduce errors, and streamline your project planning. For more details or assistance, call us at +91 22 66103554.

ReplyDeleteInformative post. Thanks for sharing.

ReplyDeletePeb exporters in Delhi

You simplify the complicated with such ease. Keep the insights flowing! Paddy Straw Grinder

ReplyDeleteFantastic deep dive into the role of steel and glass in architecture! I especially appreciate how you explore both historical context and practical building elements — it really highlights how these materials shape modern design. For anyone interested in combining cutting-edge functionality with steel and glass aesthetics, services like Automatic Door Installation in Ontario bring seamless, modern entrances to commercial and residential projects, enhancing both accessibility and style. Keep up the great work!

ReplyDeleteThis was an interesting and engaging read. I truly appreciate the effort behind this content.

ReplyDeleteFor those looking to learn about Qadiani, you can find complete information at emaanekamil.com.

Looking for an effective gpt 표절 률 낮추는 사이트? Our platform helps you reduce plagiarism rates efficiently while maintaining original content quality. You can also перефразувати текст з ші easily, transforming AI-generated text into unique, readable versions. Perfect for students, writers, and professionals who want reliable content modification and paraphrasing solutions. With advanced algorithms, our service ensures your text remains coherent, natural, and plagiarism-free. Experience fast, accurate, and user-friendly tools for all your rewriting needs today.

ReplyDeleteEnhance your space with stunning canvas prints, wood prints, and fine art designed to inspire. Our collection features vibrant acrylic wall art and sleek acrylic prints, perfect for adding elegance to any room. Whether decorating your home office or selecting the best wall art for living room, our pieces combine style and quality. Transform your walls with art that reflects your personality and taste, creating a welcoming and sophisticated atmosphere in every corner of your home.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteFind Top 5 Suppliers of 904L Stainless Steel Tubing in Saudi Arabia. Find Stainless Steel 904L Pipe Stockists in Saudi Arabia with an Excellent Durability.

ReplyDeleteFor more details or assistance, call us at +966 555244368.