This work was done about 18 months ago. You might think that urinals are fairly disgusting objects, (in practice they quite often are) but is that an excuse for the pathetic state of current Revit content for this very useful piece of equipment ? That's roughly what I was thinking when I set about the task of creating some urinals that could sit proudly alongside my classy toilet content (like peas in a pod)

The first one is generic. I didn't have a particular model in mind, but the general shape and size is very common. I had previously tried to tackle this in Point World with little success. After that, almost every time I took a walk down the corridor my mind would drift to puzzling out the geometry ... it can't be that hard, surely ?

One solid half-revolve cut by two voids gets us pretty close. The extrusion cuts across sideways, and the void revolve hollows out the bowl. In reality there are usually more subtleties than this, but I'm not looking for an exact replica. Families aren't instructions for making things ... plumbing families certainly aren't. They are there to represent an object. I want them to be roughly the right size and shape, look good in orthographic views, not offend the eye in 3d shaded views, and render up fairly convincingly.

The basic form is almost there, but the sharp edges offend my eyes. So we export in a solid format (ACIS / SAT) so we can do some rounding off of complex curves in another application. I notice that I was using Inventor Fusion at first. This is probably the only time I ventured into that territory. Later on I realised that the same operation was available in Autocad.

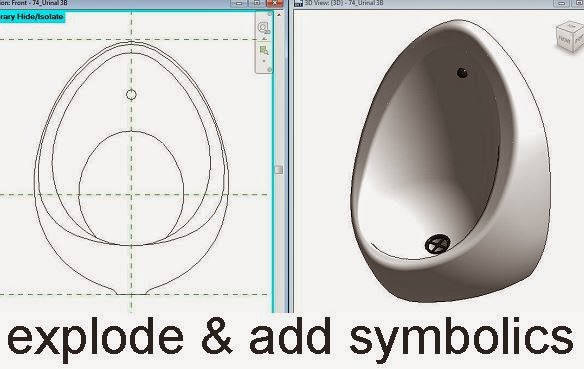

Back in Revit you can explode the geometry to create a free-form solid that accepts material parameters. Hide this in orthographic views and replace with symbolics. (masking regions and symbolic lines) I think it is important to do all 3 views (top, side, front) We often do internal elevations of washrooms with tile setting out etc etc. Nothing like clean crisp symbolics to make these look good. If your geometry has sharp edges and is fairly simple, then you may not need symbolics (a table for example) But rounded, nurbs-like forms are unlikely to show up well in a hidden line elevation.

My next peapod is based on the Duravit Arc. I didn't have a 3d download for this, just working from dimensioned jpegs. That's more than adequate for what I want to do.

Actually this one is not very difficult. Looks a bit scary if you select all the geometry: solids and voids all over the place.

But it's not hard to figure out for anyone with a bit of experience with family editor. (Vanilla this time) Important to set up a named work plane for the angled cylinder

Once again the secret to making rendered views convincing is the softening of the edges so that they pick up the right kind of reflections.

Excited by my progress I went on to set up a rendered view on a tiled background. This is a fairly low-res version by it gets the message across. As far as I am concerned, this is a huge improvement on the urinal families that I have found on the web. I even got excited enough to model a towel draped over a towel rail. Nothing difficult in that, just a sweep, but taking care to shape both the path and the profile as gentle curves.

I'm not going to describe all these fittings in great detail. I went on to make the Vero, McDry, Bill and Starc 1 (all Duravit) Other manufacturers have similar looking models so they could be useful even when you are not specifying Duravit.

The Vero is a fairly straightforward modelling exercise in Vanilla mode. Later on I adapted this to create a "Series" urinal & screen by RAK ceramics. RAK are our local UAE manufacturers of ceramics producing good quality sanitary ware and tiles that are very competitive in the regional market.

McDry was modelled in point world. As the name implies, this is a waterless type of urinal. I haven't got around to exporting to SAT and rounding the edges on this yet.

The Bill is a slightly more elaborate modelling task, so I opted for using a CAD import for the moment and used my time to create the symbolic work in plan and elevation. (This is DWG, not SAT, so everything vanishes if you try to explode it) It's interesting to note that the orthographic views provided as downloads don't match the 3d file. The boundaries are pretty much the same, but the internal lines (intended to represent 3d curves) are quite different. I've noticed this before with downloads from other sources. It doesn't matter much to me. As long as the "footprint" is accurate and the overall impression is convincing, that's all I really want.

The first one is generic. I didn't have a particular model in mind, but the general shape and size is very common. I had previously tried to tackle this in Point World with little success. After that, almost every time I took a walk down the corridor my mind would drift to puzzling out the geometry ... it can't be that hard, surely ?

One solid half-revolve cut by two voids gets us pretty close. The extrusion cuts across sideways, and the void revolve hollows out the bowl. In reality there are usually more subtleties than this, but I'm not looking for an exact replica. Families aren't instructions for making things ... plumbing families certainly aren't. They are there to represent an object. I want them to be roughly the right size and shape, look good in orthographic views, not offend the eye in 3d shaded views, and render up fairly convincingly.

The basic form is almost there, but the sharp edges offend my eyes. So we export in a solid format (ACIS / SAT) so we can do some rounding off of complex curves in another application. I notice that I was using Inventor Fusion at first. This is probably the only time I ventured into that territory. Later on I realised that the same operation was available in Autocad.

Back in Revit you can explode the geometry to create a free-form solid that accepts material parameters. Hide this in orthographic views and replace with symbolics. (masking regions and symbolic lines) I think it is important to do all 3 views (top, side, front) We often do internal elevations of washrooms with tile setting out etc etc. Nothing like clean crisp symbolics to make these look good. If your geometry has sharp edges and is fairly simple, then you may not need symbolics (a table for example) But rounded, nurbs-like forms are unlikely to show up well in a hidden line elevation.

My next peapod is based on the Duravit Arc. I didn't have a 3d download for this, just working from dimensioned jpegs. That's more than adequate for what I want to do.

Actually this one is not very difficult. Looks a bit scary if you select all the geometry: solids and voids all over the place.

But it's not hard to figure out for anyone with a bit of experience with family editor. (Vanilla this time) Important to set up a named work plane for the angled cylinder

Once again the secret to making rendered views convincing is the softening of the edges so that they pick up the right kind of reflections.

Excited by my progress I went on to set up a rendered view on a tiled background. This is a fairly low-res version by it gets the message across. As far as I am concerned, this is a huge improvement on the urinal families that I have found on the web. I even got excited enough to model a towel draped over a towel rail. Nothing difficult in that, just a sweep, but taking care to shape both the path and the profile as gentle curves.

I'm not going to describe all these fittings in great detail. I went on to make the Vero, McDry, Bill and Starc 1 (all Duravit) Other manufacturers have similar looking models so they could be useful even when you are not specifying Duravit.

The Vero is a fairly straightforward modelling exercise in Vanilla mode. Later on I adapted this to create a "Series" urinal & screen by RAK ceramics. RAK are our local UAE manufacturers of ceramics producing good quality sanitary ware and tiles that are very competitive in the regional market.

McDry was modelled in point world. As the name implies, this is a waterless type of urinal. I haven't got around to exporting to SAT and rounding the edges on this yet.

The Bill is a slightly more elaborate modelling task, so I opted for using a CAD import for the moment and used my time to create the symbolic work in plan and elevation. (This is DWG, not SAT, so everything vanishes if you try to explode it) It's interesting to note that the orthographic views provided as downloads don't match the 3d file. The boundaries are pretty much the same, but the internal lines (intended to represent 3d curves) are quite different. I've noticed this before with downloads from other sources. It doesn't matter much to me. As long as the "footprint" is accurate and the overall impression is convincing, that's all I really want.

So I have at least 4 different strategies to choose from when modelling sanitary ware depending on my source material.

- I can use a 3d CAD import and apply materials via Object Styles/imports in families.

- I can explode the CAD import (if it's a true solid, like SAT format)

- I can model in vanilla Revit

- I can model in Point World, export to SAT, re-import and explode

Option 3 is first choice: small file sizes and directly applied material parameters

Option 4 is good for curvaceous shapes, but go easy on the edge fillets and expect file sizes of between 1 and 2mb

Option 2 is fast and easy, but only possible if the right kind of download is available (rare)

Option 1 is also fast, but end users need to understand how the materials assignments work and you will have undesirable seams in shaded views.

In my view they are all useful methods which can help us to assemble a much better library of Plumbing Fixture content.

More to come, including access to my work-in-progress Duravit families. Stay tuned :-)

thank for the wonderful post , lots of information gained , visit us Revit Modeling in uk

ReplyDelete